Friday update

Almost finished with the cowling. I may be over doing it a bit but I want the cowling to fit and look just right. I'm almost there, just working out the location of the Dzus fasteners so that everything fits nice and tight and straight. Also the Dzus fasteners require a tool that we don't have. Might need to buy or borrow one. Meanwhile I've been continuing to route the engine plumbing.

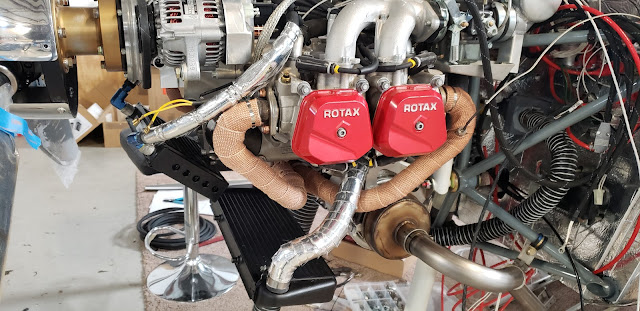

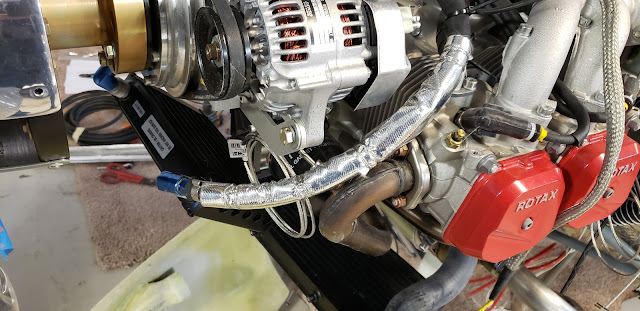

Temporarily mounted the radiator and oil cooler but will need to remove and install several times. Need to buy more Sikaflex to seal around the coolers in the lower cowl. I use plastic wrap to protect the radiator and oil cooler and then glue them in with Sikaflex. The when cured I remove them from the plastic wrap and trim the Sikaflex to make it neat. Need to do this one more time and they'll be in correctly. Oil line routing is almost complete. Need to purchase the crimp tool for the ear style hose clamps. Radiator lines are in place and only need to be clamped. Under cowl wiring is being initially routed just to see where everything goes.

Checking wire lengths for trimming. It looks a mess but once the routing is decided the rest goes quickly. Have temporarily placed Adel clamps and have begun to use wire ties to locate and secure hoses and wire bundles. Have the air cleaner assembly installed.