I contacted the factory about the 108% TCU setting at the 100% throttle position and this was their response (I added some notes):

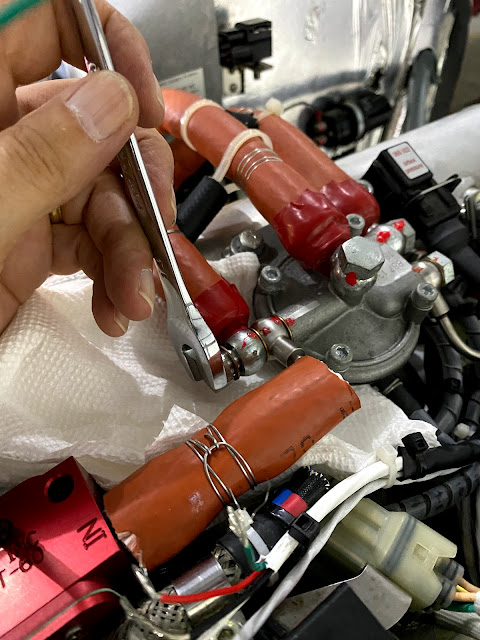

- Set the throttle lever on the quadrant to the 100% stop, then adjust the throttle cable on the left carb from 108% down to 100% (as read from the TCU software in Monitor mode).

- Next, you will have to balance the right-hand carb the same at the left (using the usual Rotax carb balancing procedure).

- With the throttle set up correctly, the TPS will provide the correct reading to the TCU. If there is slack in the TCU cable it can be adjusted but avoid excessive tension.

I asked them if I can defer fixing this as long as I keep the MAP below Rotax specified max values and they said yes (as expected). So, I'll keep it below 40" for the takeoff sequence (5-minute max) and below 35" continuous otherwise.

It's clear that this is yet another thing that was not done in Oklahoma...