Flight to Provincetown on Cape Cod with Ellen! Fun!

Craig's Sling 4 Build Log

Categories

Sunday, September 1, 2024

Friday, August 9, 2024

Friday, June 2, 2023

Monday, January 23, 2023

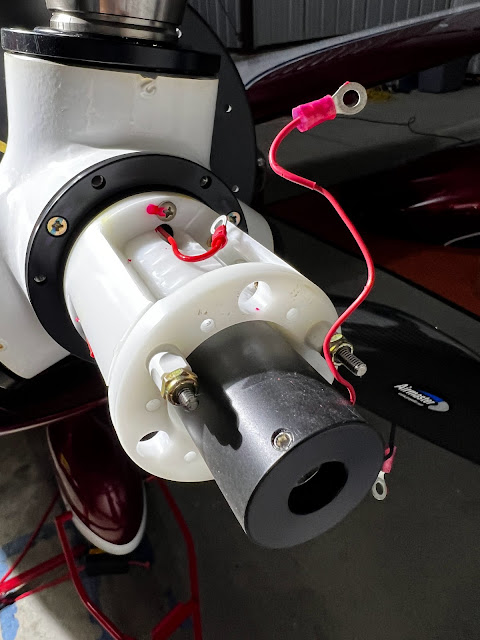

Further debugging and it looked like the pitch motor itself had failed. Voltage applied directly to the motor did not move the motor at all.

Turns out that the motors in Airmaster props older than a year (give or take) have a design prone to open circuit failures. So much so that they completely redesigned the motor and there are formal instructions for replacing the motor. The new motor is more robust and faster in changing the pitch too.

My new pitch motor arrives on Wednesday (thankfully covered under warranty). I'll have to update the controller parameters with this change and I've already got that file. I'll also update the controller firmware while I'm at it.

Photos show the disassembly of the hub to remove the pitch motor itself, which I'm holding in the last photo.

Sunday, December 25, 2022

Monday, December 19, 2022

I don't have any pictures, but I wanted to pass along how my last flight went. This was the first flight since installing the preheater and the back seat seal and both worked like a champ.

The day was quite cold (upper 20sF (about -2.7C)), so I had turned on the preheater the night before. On startup, the oil temp was almost instantly about 90F and ran smoothly from the first crank. My experience on prior cold starts was that it would run pretty roughly for the first few minutes. Not this time at all. Smooth as silk.

Up in the air, I found the cabin quite comfortably warm. That's never happened before on cold days. The draft from the back seat was quite strong and as far as I could tell from the front seat, that was totally gone.

Big wins for winter flying!