Very useful video on rod end bearings and fire extinguishers from Vic Syracuse.

Categories

Sunday, December 25, 2022

Monday, December 19, 2022

I don't have any pictures, but I wanted to pass along how my last flight went. This was the first flight since installing the preheater and the back seat seal and both worked like a champ.

The day was quite cold (upper 20sF (about -2.7C)), so I had turned on the preheater the night before. On startup, the oil temp was almost instantly about 90F and ran smoothly from the first crank. My experience on prior cold starts was that it would run pretty roughly for the first few minutes. Not this time at all. Smooth as silk.

Up in the air, I found the cabin quite comfortably warm. That's never happened before on cold days. The draft from the back seat was quite strong and as far as I could tell from the front seat, that was totally gone.

Big wins for winter flying!

Monday, December 5, 2022

Friday, November 11, 2022

I got my shipment of the new brush (actually I ordered 3 in case of future failures) from New Zealand. 3 days door-to-door. Not bad.

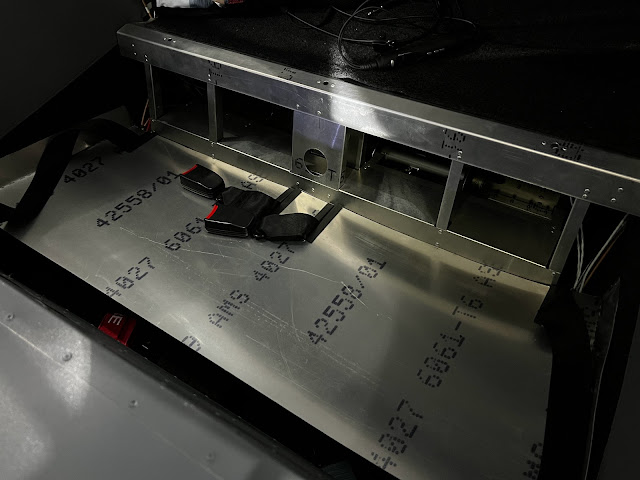

The assembly before starting. I had already desoldered and removed the wire from the center pad.

Sunday, November 6, 2022

On my last couple of flights, I saw a failure indication on the Airmaster prop controller. 3 Flashing red lights, which means there's an open circuit to the prop. It was intermittent, but I grounded the plane until it was figured out.

First I checked the sliprings behind the gearbox on which the triple carbon brushes ride. They seemed fairly smudgy so I cleaned them gently with a Scotchbrite pad. Nope, that didn't make a difference.

Then I looked behind the panel on both sides to look for any loose wires and didn't find anything (I was also searching for loose grounds that might be related to the audio static).

Since nothing turned up it was time to take a look at the brush assembly since I've heard of others having issues with those.

Monday, October 17, 2022

Been flying Sadie lately and also trying to figure out the static I'm hearing when the co-pilot's side mic jack is plugged in (which it usually is). Pull it out and the static goes away. Hmm..

It's in an awkward spot, but I could feel that the connections were solid to the co-pilot's mic jack. I did notice though that one of the wires was pressing against one of the spring contacts (coupling causing static?). I managed to push it away using a dentist's pick, so we'll see if that helps.

Monday, September 26, 2022

Haven't posted in a while, but it's been fun flying Sadie. I don't know if I posted about the solution to the low RPM, but it was a stuck turbo. Apparently, it was shut down without a cool-down on a hot day and sometimes the turbo can get stuck. The only solution was to pull the cowling, remove the air filter and spin the turbo by hand to un-stick it. That worked!

The last thing I was dealing with was erratic engine sensors, which turned out to be another loose ground on a "CHT" sensor. The more recent 914 engines measure coolant temp, not CHT. There are two, but they're measuring the same thing, so the factory only uses one. So, I simply turned off the one with the loose ground in the G3X and clipped that ground. With that done, all is well.

Other than that I've been checking the eyebolts in regards to the recent service notice and so far they've all been the correct types. Whew.... I really didn't want to have to change those and so far, so good.

Thursday, August 4, 2022

Wednesday, August 3, 2022

Well, the engine and plane were perfectly fine on flights this past Sunday and Monday, but then this happened on Tuesday... Barely starts and even if advancing the throttle it won't get above about 780 RPM.

It looks like it's drawing only from the battery and never from either of the alternators. That's not sustainable, right?

Thoughts?

Monday, July 11, 2022

Lots of flying the past few days. 3 flights: An instrument training flight to New Bedford Regional, a flight to Martha's Vineyard's Katama Airfield, and a local sightseeing flight to a popular mountain for hiking, Mt. Monadnock.

Me and Mike Emery on our way to Martha's Vineyard.