1 hr. peeling plastic off of the VS skin... Still not done...

Categories

ailerons

(16)

avionics

(141)

electrical

(180)

elevator

(23)

Empennage

(55)

firewall forward

(222)

flaps

(12)

fuel cells

(68)

fuselage

(596)

horizontal stabilizer

(14)

instructions

(3)

interior

(104)

paint

(36)

Painting Planes

(3)

panel

(67)

propeller

(3)

rudder

(16)

seats

(5)

ServiceBulletin

(1)

shop

(33)

Sling Central

(23)

tools

(41)

vertical stabilizer

(20)

video

(37)

welcome

(22)

wheels

(44)

wings

(147)

Sunday, October 26, 2014

Friday, October 24, 2014

2 hrs finished up the fabrication of the top rib of the vertical stabilizer which contains the VOR antenna, created the holes in the skin through which the antenna and hex key pokes through and riveted the rib to the mounting channel.

Make sure the skin is on and lined up for marking the inside of the skin where it will be drilled through.

View on the inside where it will be marked for the antenna hole and hex key hole. A set for each side.

Marked off for drilling and filing.

After a couple of test fits and lots of filing to fine-tune it, it fits!

Ready to be attached. But first I needed to drill into the 4 rivet holes nearest the VOR "puck" so that the shortened rivets can be inserted.

And it's riveted on! Next I'll construct the cable for the VOR, snake that through (how did Gordon do it?) and snake the 4-core lighting wire through the grommets already installed.

Make sure the skin is on and lined up for marking the inside of the skin where it will be drilled through.

View on the inside where it will be marked for the antenna hole and hex key hole. A set for each side.

Marked off for drilling and filing.

After a couple of test fits and lots of filing to fine-tune it, it fits!

Ready to be attached. But first I needed to drill into the 4 rivet holes nearest the VOR "puck" so that the shortened rivets can be inserted.

And it's riveted on! Next I'll construct the cable for the VOR, snake that through (how did Gordon do it?) and snake the 4-core lighting wire through the grommets already installed.

Wednesday, October 22, 2014

1.5 hrs working on the VS. Continuing work on the top rib for the VOR antenna install.

Taped off around the antenna so I know where on the skin to cut the exit hole.

Just got these precision files today - just in time for the fine-tuning of the holes in the flanges of the rib. I added a new tag word, "tools" for any tool related posts.

Here's the taped-off hole and the drilled and filed hole for the hex key (where the line is drawn vertically so I knew where the pilot hole would be drilled).

The hex key fits!

Taped off around the antenna so I know where on the skin to cut the exit hole.

Just got these precision files today - just in time for the fine-tuning of the holes in the flanges of the rib. I added a new tag word, "tools" for any tool related posts.

Here's the taped-off hole and the drilled and filed hole for the hex key (where the line is drawn vertically so I knew where the pilot hole would be drilled).

The hex key fits!

Sunday, October 19, 2014

1.5 hrs working on the VOR installation on the top rib of the VS.

For connecting the stiffener plate to the top rib why was I getting these mis-drilled holes? I was keeping the drill straight and it was a new bit, so I don't understand. The rivets were tight and there was more than necessary so I'm not concerned about the security of the mating.

Plate connected and the VOR in place for the drilling of the mounting holes for it.

Drilled (3/16" drill bit) and in place. Nice!

What the flip side looked like. Next up will be the placement and drilling of the small holes (one on each side) for the hex key to be able to be inserted (tightening with the key secures the antenna in place).

For connecting the stiffener plate to the top rib why was I getting these mis-drilled holes? I was keeping the drill straight and it was a new bit, so I don't understand. The rivets were tight and there was more than necessary so I'm not concerned about the security of the mating.

Plate connected and the VOR in place for the drilling of the mounting holes for it.

Drilled (3/16" drill bit) and in place. Nice!

What the flip side looked like. Next up will be the placement and drilling of the small holes (one on each side) for the hex key to be able to be inserted (tightening with the key secures the antenna in place).

Saturday, October 18, 2014

1.5 hrs test fitting the skin on the rudder and riveting the rudder structure.

Testing the hinge connections of the vertical stabilizer to the rudder. Good to go!

Test fit of the skin on the rudder.

Hmm, a twist of the trailing edge. I think when I'm going to rivet the skin I just need to be cognizant of any twist of the trailing edge.

Detail photo of the bottom of the mounting channel of the rudder.

Bottom of the rudder.

Note how the bends of that bottom piece point up.

Detail of the top of the rudder channel.

Now with the top rib installed.

Uh oh... The holes are missing from the bottom two ribs for the connection of the strengthening rib. Perhaps I got the Sling 2 ribs? I'll have to figure out how to locate where to drill the holes...

Testing the hinge connections of the vertical stabilizer to the rudder. Good to go!

Test fit of the skin on the rudder.

Hmm, a twist of the trailing edge. I think when I'm going to rivet the skin I just need to be cognizant of any twist of the trailing edge.

Detail photo of the bottom of the mounting channel of the rudder.

Bottom of the rudder.

Note how the bends of that bottom piece point up.

Detail of the top of the rudder channel.

Now with the top rib installed.

Uh oh... The holes are missing from the bottom two ribs for the connection of the strengthening rib. Perhaps I got the Sling 2 ribs? I'll have to figure out how to locate where to drill the holes...

Sunday, October 12, 2014

2.5 hrs working on the vertical stabilizer.

Figuring out how the VOR antenna will fit in the top rib of the VS. Note the thick mounting plate which I made.

The antennas will go through the widened gaps in the flanges.

Side view

Here I've widened the gaps for the antennas. I'll need to drill into the VOR Balun somewhat in order for the shortened rivet to be inserted.

Top view

Nice rivets!

The rivets at the bottom of the VS mounting channel. These 4 (2 each side) go all the way through as opposed to the other 14 added before (some of which you can see here).

Figuring out how the VOR antenna will fit in the top rib of the VS. Note the thick mounting plate which I made.

The antennas will go through the widened gaps in the flanges.

Side view

Here I've widened the gaps for the antennas. I'll need to drill into the VOR Balun somewhat in order for the shortened rivet to be inserted.

Top view

Nice rivets!

The rivets at the bottom of the VS mounting channel. These 4 (2 each side) go all the way through as opposed to the other 14 added before (some of which you can see here).

Saturday, October 11, 2014

3.5 hrs working on the vertical stabilizer.

Got my new angle drill attachment kit yesterday! Very exciting! :-) Got it for about $70 on Amazon.

The rudder strobe light wire will go through here. Turns out it's not easy to put grommet edging in!

Smaller grommets installed in the VS. Note that the bottom-most one is in the center not near the mounting channel like shown in the instructions. Peter Calley's blog indicates that that is how it's done at the factory (because that's where the connections are under the VS) and that the instructions are wrong. All the holes are drilled out to 3/8".

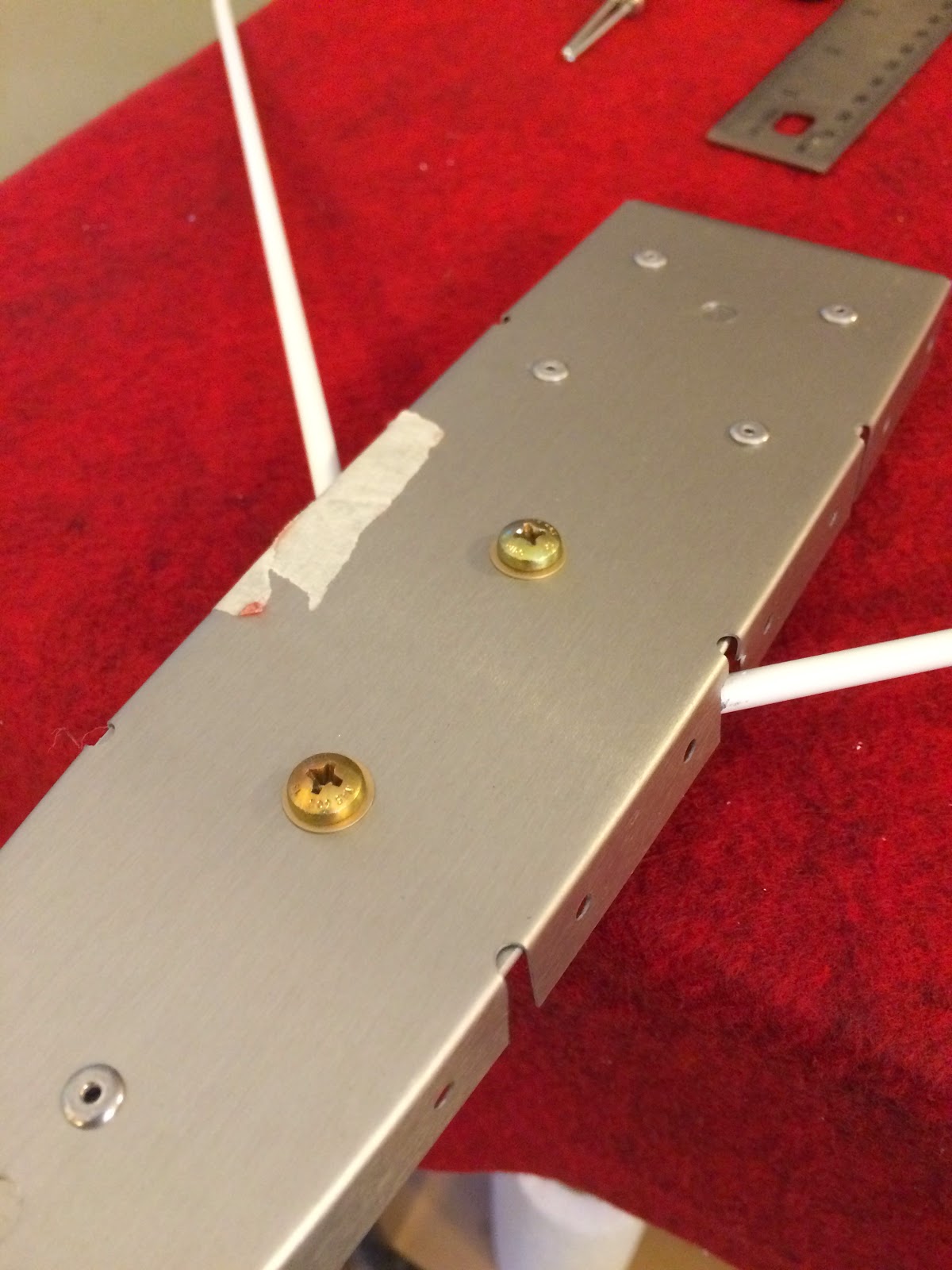

Some of the holes will not be riveted at this point, so I've marked those with a tic mark. 8 holes in this photo.

4 holes in this photo are tic marked because I should not rivet them now.

A couple here on each side that won't be riveted at this time (even after the skin is on).

Test fit of the VS skin. It fits!

Another view of the test fit. The top rib needs to be worked on to install the VOR antenna. A bit of fab work will be required.

Got my new angle drill attachment kit yesterday! Very exciting! :-) Got it for about $70 on Amazon.

The rudder strobe light wire will go through here. Turns out it's not easy to put grommet edging in!

Smaller grommets installed in the VS. Note that the bottom-most one is in the center not near the mounting channel like shown in the instructions. Peter Calley's blog indicates that that is how it's done at the factory (because that's where the connections are under the VS) and that the instructions are wrong. All the holes are drilled out to 3/8".

Some of the holes will not be riveted at this point, so I've marked those with a tic mark. 8 holes in this photo.

4 holes in this photo are tic marked because I should not rivet them now.

A couple here on each side that won't be riveted at this time (even after the skin is on).

Test fit of the VS skin. It fits!

Another view of the test fit. The top rib needs to be worked on to install the VOR antenna. A bit of fab work will be required.

Thursday, October 9, 2014

Thinking about how to go about the radio cabling and decided that I can easily do my own cable assemblies (hey, I am an electrical engineer after all...;-)).

I'll use the recommended certified RG-400 coax. Now I need to figure out how much I'll need for the whole plane - it's pretty expensive stuff, so I don't want to buy more than I need.

I found this video that shows how to put a BNC connector on the cable (so easy! :-)):

I'll use the recommended certified RG-400 coax. Now I need to figure out how much I'll need for the whole plane - it's pretty expensive stuff, so I don't want to buy more than I need.

I found this video that shows how to put a BNC connector on the cable (so easy! :-)):

Tuesday, October 7, 2014

1.5 hrs. test fit of the VS and installing rivnuts,

Had to ream out the holes a bit so the rivnuts fit.

Ready for the pull! Note that the tool part that screws into the rivnut should stick out of it a bit.

After the pull, a nice mushroom.

This is the tool required.

One of the holes on each side is not properly sized on my parts (yours may be fine!), so I'll need to drill that out to size before I can fit the 7th rivnut on both sides.

Had to ream out the holes a bit so the rivnuts fit.

Ready for the pull! Note that the tool part that screws into the rivnut should stick out of it a bit.

After the pull, a nice mushroom.

This is the tool required.

One of the holes on each side is not properly sized on my parts (yours may be fine!), so I'll need to drill that out to size before I can fit the 7th rivnut on both sides.

Sunday, October 5, 2014

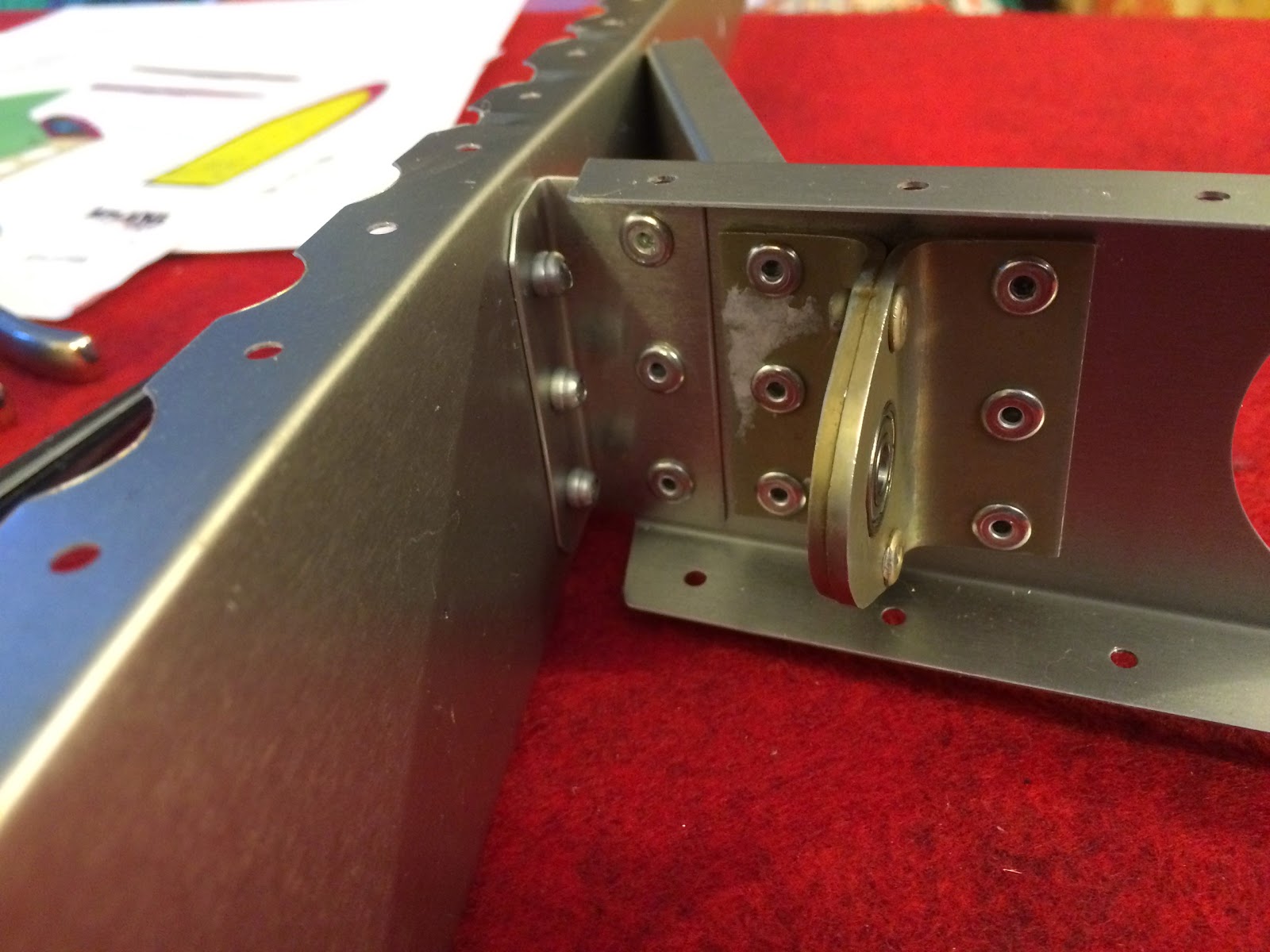

3 hrs. priming VS & rudder parts and then fitting together rudder parts. Found that the holes of rudder Hinge Bracket 3 did not line up with the holes of the rudder Mounting Channel.

Uh oh, the holes don't line up...

Back side view.

The mounting channel holes are about 30mm center to center. The hinge is less (not measured).

Uh oh, the holes don't line up...

Back side view.

The mounting channel holes are about 30mm center to center. The hinge is less (not measured).

Subscribe to:

Comments (Atom)