0 hrs. on the plane today.... Full day of family activities related to my older daughter getting married in June. 😁

But, I looked at the plane and took a picture. 😎

Did update the Task List with more details related to populating the firewall.

Also, anybody know (I'll ask the factory too) if this fuel hose is appropriate for Sling use? Like, does it fit the fittings for the fuel switch, etc.? If so, what size?

Categories

ailerons

(16)

avionics

(141)

electrical

(180)

elevator

(23)

Empennage

(55)

firewall forward

(222)

flaps

(12)

fuel cells

(68)

fuselage

(596)

horizontal stabilizer

(14)

instructions

(3)

interior

(104)

paint

(36)

Painting Planes

(3)

panel

(67)

propeller

(3)

rudder

(16)

seats

(5)

ServiceBulletin

(1)

shop

(33)

Sling Central

(23)

tools

(41)

vertical stabilizer

(20)

video

(37)

welcome

(22)

wheels

(44)

wings

(147)

Sunday, March 31, 2019

Saturday, March 30, 2019

1.5 misc.

Checked in with the factory on what gets mounted on the firewall and they confirmed my list. Here's the list again with notations as to whether I have that located:

Most of the above mentioned parts that I've located.

My engine! 😁

The 6mm fuel return hose.

This is all I've found of the 8mm fuel hose. Surely doesn't seem like enough. Anybody have a USA source?

Checked in with the factory on what gets mounted on the firewall and they confirmed my list. Here's the list again with notations as to whether I have that located:

- 2 GPS brackets and units: One for G3X and one for 650 YES

- Fuel Pump and cover Cover YES, Fuel Pump, NO (come with the engine? A quick look in the engine crate and I don't see it).

- Oil Tank/Bracket YES (oil tank came with engine)

- Brake Reservoir Bracket YES

- Overflow Bottle/Bracket YES

- Battery and its mounting box YES

- Starter Relay (diode mounted on relay) YES

- Master Relay (diode mounted on relay) YES (Factory says this is mounted on the cabin side, but that doesn't make sense to me since it connects with the starter relay. Thoughts?)

- 2 slow-blow fuses YES

- Cabin Heat Splitter Box YES

- TCU NO (Come with the engine? A quick look in the engine crate and I don't see it)

- Turbo Servo NO (Come with the engine? A quick look in the engine crate and I don't see it)

- Ambient Pressure Sensor NO (Come with the engine? A quick look in the engine crate and I don't see it)

- Grounding Bolt YES

On the cabin side I have:

- Regulator YES (came with engine)

- Cabin Heat Inside Cover YES

If anybody has any info on the above red notes, I'd appreciate it.

As I expected the factory recommends installing the engine-side items before mounting the engine due to limited space.

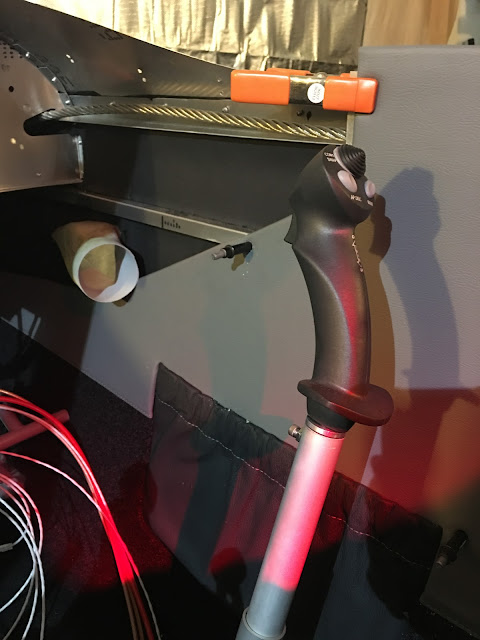

Had this one last piece (control stick assembly cover) to do.

Most of the above mentioned parts that I've located.

My engine! 😁

The 6mm fuel return hose.

This is all I've found of the 8mm fuel hose. Surely doesn't seem like enough. Anybody have a USA source?

Thursday, March 28, 2019

Haven't had time to work on the plane, but I have bought a couple of tools. 😁 I'm kind of a sucker for useful tools.

I have a nibbler, but it's pneumatic and that's a pain... I recently stumbled across this cool tool which is a versatile nibbler that uses your drill. Good for cutting circles, curves, etc. This would have been a better tool to use to cut that notch for the wiring the other day.

I read an article in Kitplanes the other day (from the guy that does HomebuiltHelp) that recommended this tool for cutting straight lines in sheet metal. Using a straight edge, you just score the sheet a few times with this knife (not going the whole way through) and then just snap it off. Much cleaner line (and way easier!) than using snips which I think are a real pain to use (especially if it's thick sheet) and don't give you the cleanest lines.

I have a nibbler, but it's pneumatic and that's a pain... I recently stumbled across this cool tool which is a versatile nibbler that uses your drill. Good for cutting circles, curves, etc. This would have been a better tool to use to cut that notch for the wiring the other day.

I read an article in Kitplanes the other day (from the guy that does HomebuiltHelp) that recommended this tool for cutting straight lines in sheet metal. Using a straight edge, you just score the sheet a few times with this knife (not going the whole way through) and then just snap it off. Much cleaner line (and way easier!) than using snips which I think are a real pain to use (especially if it's thick sheet) and don't give you the cleanest lines.

Wednesday, March 27, 2019

I'm planning to start very soon on the firewall and want to know if I have everything that gets mounted on the engine side of the firewall in this list:

- 2 GPS brackets and units: One for G3X and one for 650

- Fuel Pump and cover

- Oil Tank/Bracket

- Brake Reservoir Bracket

- Overflow Bottle/Bracket

- Battery and its mounting box

- Starter Relay (diode mounted on relay)

- Master Relay (diode mounted on relay)

- 2 slow-blow fuses (?)

- Cabin Heat Splitter Box

- TCU

- Turbo Servo

- Ambient Pressure Sensor

- Grounding Bolt

- Missing anything? Electrical components I didn't capture?

On the cabin side I have:

- Regulator

- Cabin Heat Inside Cover

- Missing anything?

I'd also like to know what must be installed before mounting the engine and what's better to wait until after the engine is mounted (if anything).

Thoughts?

Sunday, March 24, 2019

2 hrs. misc.

After sanding all the rivets I filled yesterday I figured it was as a good a time as any to finish the inspection ports under the fuselage. M3 rivnuts in.

The nylon washers I use under the M3 screws.

And in place. A little back-breaking working under the fuselage... Since you're inserting a rivnut from below it especially important to keep the rivnut pressed up against the fuselage while you pull it otherwise it could start to expand while not fully inserted - a pain to fix. I didn't do that today, but I've done it in the past...

Other port in.

Also made pizza from scratch tonight. Like my apron? 😁

With roasted garlic and sausage. Delicious.

After sanding all the rivets I filled yesterday I figured it was as a good a time as any to finish the inspection ports under the fuselage. M3 rivnuts in.

The nylon washers I use under the M3 screws.

And in place. A little back-breaking working under the fuselage... Since you're inserting a rivnut from below it especially important to keep the rivnut pressed up against the fuselage while you pull it otherwise it could start to expand while not fully inserted - a pain to fix. I didn't do that today, but I've done it in the past...

Other port in.

Also made pizza from scratch tonight. Like my apron? 😁

With roasted garlic and sausage. Delicious.

Have you done any of the DNA tests? I have and it's very cool! If you go back to 4th cousins, you probably have relatives all over the world! Here are my 4th cousin relatives in Australia!! Those numbers represent the number of related people in that area. Wow! 😎

Saturday, March 23, 2019

3.5 hrs. on the interior and some exterior (filled the remaining rivets on the rear right side/top of the fuselage).

Using some small drill bits and a step drill I created a notch on the side of the cross member.

Adding some edge grommets I'm happy with this solution for getting those wires down.

Same thing other side.

Decided I was clear to put the side panels in more permanently.

Just another view.

Using some small drill bits and a step drill I created a notch on the side of the cross member.

Adding some edge grommets I'm happy with this solution for getting those wires down.

Same thing other side.

Decided I was clear to put the side panels in more permanently.

Just another view.

Thursday, March 21, 2019

1 hr. of slightly less futzing on the interior.

The rear seat comes fairly close to the side walls, so not much room to route the wires down... Maybe I'll cut a notch from the side. Hmm..

Ideally the headphone wires would have gone through a hole in that rib (as I saw at least one other person did), but I didn't know at the time it would be OK to poke a large hole through it (is that OK?). I can live with it going around the rib.

I did add some edge grommet after this photo was taken where the wires pass over that cross piece.

Just tidied up the wiring on this side.

The rear seat comes fairly close to the side walls, so not much room to route the wires down... Maybe I'll cut a notch from the side. Hmm..

Ideally the headphone wires would have gone through a hole in that rib (as I saw at least one other person did), but I didn't know at the time it would be OK to poke a large hole through it (is that OK?). I can live with it going around the rib.

I did add some edge grommet after this photo was taken where the wires pass over that cross piece.

Just tidied up the wiring on this side.

Wednesday, March 20, 2019

Monday, March 18, 2019

A deep analysis of the MCAS system on the 737 Max.... Here.

Wearing my engineering hat more than my pilot hat, I'd say that Boeing is in deep sh... over this...

Lots of bad engineering and management decisions to push the product out into the market as soon as possible.

Sunday, March 17, 2019

3 hrs. on the interior.

Have I mentioned that you have to do a lot of vacuuming? Well, you do... Lots of debris to keep up with.... A portable vacuum works well. I use ear protection when I'm using it in the cockpit since it can be quite loud.

See the debris... 😁 From reaming it out first to M3 then M4 rivnut size.

Rivnuts in... BTW, I don't deburr these holes because I think it's actually good to leave burrs on holes for rivnuts - something to dig into the rivnuts to make it less likely they'll ever rotate. FYI: It's a pretty hard pull to get the rivnuts in the fiberglass.

Don't forget the Loctite 277!

A test of pulling of a rivnut to make sure it's not too little or too much.

After all the rivnuts were in I put in the panels and then the rear seat (at least temporarily). View from the back. 👌

Me. 😁

Nice view. For now I only put in every other screw for the rear panels.

Starting to look pretty comfortable...

Have I mentioned that you have to do a lot of vacuuming? Well, you do... Lots of debris to keep up with.... A portable vacuum works well. I use ear protection when I'm using it in the cockpit since it can be quite loud.

See the debris... 😁 From reaming it out first to M3 then M4 rivnut size.

Rivnuts in... BTW, I don't deburr these holes because I think it's actually good to leave burrs on holes for rivnuts - something to dig into the rivnuts to make it less likely they'll ever rotate. FYI: It's a pretty hard pull to get the rivnuts in the fiberglass.

Don't forget the Loctite 277!

A test of pulling of a rivnut to make sure it's not too little or too much.

After all the rivnuts were in I put in the panels and then the rear seat (at least temporarily). View from the back. 👌

Me. 😁

Nice view. For now I only put in every other screw for the rear panels.

Starting to look pretty comfortable...

Saturday, March 16, 2019

3 hrs. on the interior.

A bit of bending and jiggling of the front side panel is required to get it positioned. It's not quite there in this photo.

I notice that the rudder pedal can touch the side panel, so I need to make sure it's screwed down up there (factory photos don't show where it's connected in that area).

Like my head shadow? 😜 Trying to position the panels as much like the factory photos as possible.

The back of the rear side panel has the holes marked, but I notice it's not really precise...

So I measured them to be consistent all the way across. 10mm from the edge and roughly 70mm between.

Holes drilled and screw test fit through.

Making sure they stay lined up and in position.

Again, checking and rechecking the position vs. the factory photos and between each side.

Checking the clearance.

After being convinced it was properly position it was time to drill. Started near the seat belt and worked back and forward from there.

Working my way forward...

Again, tried to match what I could see in the factory photos.

Drill, drill, drill....

This area I can't see in the factory photos, but this seems like another good place to pin it down.

These two spots seem like good choice to make sure the panel is pinned against the skin. Careful with these (and all really) holes when you drill, that you're only drilling through the inner skins.... You do not want to penetrate the outer skin....

That bottom one I can't/don't see in the factory photos, but the side panel sticks out down there if you don't pin it down. Tomorrow I'll put in all the M4 rivnuts!

A bit of bending and jiggling of the front side panel is required to get it positioned. It's not quite there in this photo.

I notice that the rudder pedal can touch the side panel, so I need to make sure it's screwed down up there (factory photos don't show where it's connected in that area).

Like my head shadow? 😜 Trying to position the panels as much like the factory photos as possible.

The back of the rear side panel has the holes marked, but I notice it's not really precise...

So I measured them to be consistent all the way across. 10mm from the edge and roughly 70mm between.

Holes drilled and screw test fit through.

Making sure they stay lined up and in position.

Again, checking and rechecking the position vs. the factory photos and between each side.

Checking the clearance.

After being convinced it was properly position it was time to drill. Started near the seat belt and worked back and forward from there.

Working my way forward...

Again, tried to match what I could see in the factory photos.

Drill, drill, drill....

This area I can't see in the factory photos, but this seems like another good place to pin it down.

These two spots seem like good choice to make sure the panel is pinned against the skin. Careful with these (and all really) holes when you drill, that you're only drilling through the inner skins.... You do not want to penetrate the outer skin....

That bottom one I can't/don't see in the factory photos, but the side panel sticks out down there if you don't pin it down. Tomorrow I'll put in all the M4 rivnuts!

Subscribe to:

Comments (Atom)