Quick half hour figuring some stuff out...

Recently got a bunch of new pictures from the factory of various close-ups on the engine and now figured out the configuration of the fittings on the oil thermostat. So, I do have the right fittings for it. Also had the bracket installed upside-down, so I fixed that. Note that the manual shows a 90 deg fitting for the top left and that is not correct. It's a straight, barbed fitting. I'll be adding those pics (and some others I had) to a consolidated "Engine" page sometime over the next few days.

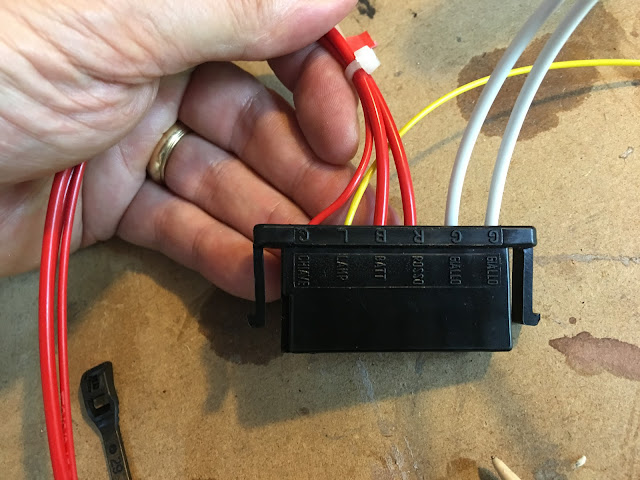

The Rotax manual only identifies one or two of these connectors, most of which are on the other end of the harness to the TCU. I'm going to ask the factory to ident them all and will post what I find out.

Categories

ailerons

(16)

avionics

(141)

electrical

(180)

elevator

(23)

Empennage

(55)

firewall forward

(222)

flaps

(12)

fuel cells

(68)

fuselage

(596)

horizontal stabilizer

(14)

instructions

(3)

interior

(104)

paint

(36)

Painting Planes

(3)

panel

(67)

propeller

(3)

rudder

(16)

seats

(5)

ServiceBulletin

(1)

shop

(33)

Sling Central

(23)

tools

(41)

vertical stabilizer

(20)

video

(37)

welcome

(22)

wheels

(44)

wings

(147)

Wednesday, July 31, 2019

Monday, July 29, 2019

Quick half hour just putting in the internal alternator relay. Then several minutes contemplating my navel (should that be a category? 😜😬)...

I had to get into the cabin to be able to easily screw in the relay (thanks Kerry for the assist). Wires still need tying down of course. I want to make sure nothing touches the regulator, which can get warm.

The other end is a big connector which plugs into the TCU, but where do these all go? Research ahead...

I had to get into the cabin to be able to easily screw in the relay (thanks Kerry for the assist). Wires still need tying down of course. I want to make sure nothing touches the regulator, which can get warm.

The other end is a big connector which plugs into the TCU, but where do these all go? Research ahead...

Sunday, July 28, 2019

After traveling today (my return from Oshkosh!) I just managed 2 hrs.

I should have taken pictures with all the people I met at the show, but sadly I didn't take any! All my pictures were of planes! But, great seeing and meeting everyone!! Some of the pictures I did take are below.

Crimped, soldered and heat shrink applied for the 6 AWG line from the grounding bolt on the firewall to the grounding block on the sub-panel (AKA top front rib). The crimp is on the opposite side from the seam of the terminal.

This is the crimper I used, which was actually easier to use than I expected for crimping a terminal on 6 gauge wire.

It's not tied down yet (nothing is), but you can see the wire behind the rib.

Now that all the wires are in place, I put in the cap. Putting in the relay will take help from a second person, so I'm holding off on that.

The new high-wing Sling TSi!! Prototype flying this year and production expected later next year. They expect to have the prototype at next year's Oshkosh.

The famous Draco!!

Ellen checking out the Sling TSi.

These guys put in the order for the 500th Sling and it was the high-wing!

DC-3 looking beautiful.

B-25 Mitchell.

And the final stop of the Oshkosh visit is to Leon's for some world class frozen custard. Yum!

I should have taken pictures with all the people I met at the show, but sadly I didn't take any! All my pictures were of planes! But, great seeing and meeting everyone!! Some of the pictures I did take are below.

Crimped, soldered and heat shrink applied for the 6 AWG line from the grounding bolt on the firewall to the grounding block on the sub-panel (AKA top front rib). The crimp is on the opposite side from the seam of the terminal.

This is the crimper I used, which was actually easier to use than I expected for crimping a terminal on 6 gauge wire.

It's not tied down yet (nothing is), but you can see the wire behind the rib.

Now that all the wires are in place, I put in the cap. Putting in the relay will take help from a second person, so I'm holding off on that.

The new high-wing Sling TSi!! Prototype flying this year and production expected later next year. They expect to have the prototype at next year's Oshkosh.

The famous Draco!!

Ellen checking out the Sling TSi.

These guys put in the order for the 500th Sling and it was the high-wing!

DC-3 looking beautiful.

B-25 Mitchell.

And the final stop of the Oshkosh visit is to Leon's for some world class frozen custard. Yum!

Tuesday, July 23, 2019

Just did an hour today... I need my hand to heal - gripped a tool and it became clear that I nicked my tendons. Lesson: Don't grab on to plane parts that resemble pizza cutters... 😬

This is what I came up with to label small gauge wire. Thin wooden "coffee stirrer" stick to stick the label on and then clear shrink tubing over that. Won't move.

Put the last connection on the internal regulator relay. I don't have the hand strength to put this on the firewall, so that will wait until I return from OSH.

Cut the 6 AWG wire for the ground connection between the sub-panel grounding block and the grounding bolt on the firewall. Again, I don't have the hand strength to crimp those terminals, so I'll do it next week.

The factory confirmed that the manual is wrong about the oil hose ID size. The manual says 5/16", but it's 12mm. Maybe they shouldn't try doing metric to English conversions?... This is the proper oil line hose.

My deep slice today. I'm sure you were anxious to see it. 😁

Hope to see some of you at the Sling Ding Party Thursday at 5!!

This is what I came up with to label small gauge wire. Thin wooden "coffee stirrer" stick to stick the label on and then clear shrink tubing over that. Won't move.

Put the last connection on the internal regulator relay. I don't have the hand strength to put this on the firewall, so that will wait until I return from OSH.

Cut the 6 AWG wire for the ground connection between the sub-panel grounding block and the grounding bolt on the firewall. Again, I don't have the hand strength to crimp those terminals, so I'll do it next week.

The factory confirmed that the manual is wrong about the oil hose ID size. The manual says 5/16", but it's 12mm. Maybe they shouldn't try doing metric to English conversions?... This is the proper oil line hose.

My deep slice today. I'm sure you were anxious to see it. 😁

Hope to see some of you at the Sling Ding Party Thursday at 5!!

Monday, July 22, 2019

4 hrs. on misc. Would have been longer... well, you'll see why it wasn't below....

This rib has been outside my house (~25 miles as the crow flies from the Atlantic Ocean) for over a year and despite enduring wet dirt, torrential rain, howling wind, blazing sun and piled on snow for weeks at a time... It shows no sign of corrosion. The left side has brushed on Cortec-373 and the right side is bare. It all looks pretty good! 6061-T6 is a great alloy!

Working on the internal alternator connectors. Crimped and soldered - going nowhere!

All in.

Connections labeled....

Standoff superglued in place... An attempt the other day to do it without gluing it failed miserably (meaning I was sweaty and miserable trying to find the standoff under the cabin side of the firewall....).

After working on firewall stuff for awhile now, it was getting pretty messy again....

So it was again time to tidy up. I feel much better! 😁

The light is super helpful when working in the cabin!

Power connection to the 22,000uF cap for the internal alt regulator.

It was way easier to put the connector on outside the cabin as it's a pretty snug fit.

While stepping down from my step stool when I was working in the cabin, I caught my foot on a loop of wire and fell... With my head careening toward the floor I grabbed the side of the fuselage, which is, well, pretty darn sharp. It sliced into my hand down to the tendons.... Pretty disturbing to see... Ouch. That brought a premature end to my work session today (I took today and tomorrow off).

This rib has been outside my house (~25 miles as the crow flies from the Atlantic Ocean) for over a year and despite enduring wet dirt, torrential rain, howling wind, blazing sun and piled on snow for weeks at a time... It shows no sign of corrosion. The left side has brushed on Cortec-373 and the right side is bare. It all looks pretty good! 6061-T6 is a great alloy!

Working on the internal alternator connectors. Crimped and soldered - going nowhere!

All in.

Connections labeled....

Standoff superglued in place... An attempt the other day to do it without gluing it failed miserably (meaning I was sweaty and miserable trying to find the standoff under the cabin side of the firewall....).

After working on firewall stuff for awhile now, it was getting pretty messy again....

So it was again time to tidy up. I feel much better! 😁

The light is super helpful when working in the cabin!

Power connection to the 22,000uF cap for the internal alt regulator.

It was way easier to put the connector on outside the cabin as it's a pretty snug fit.

While stepping down from my step stool when I was working in the cabin, I caught my foot on a loop of wire and fell... With my head careening toward the floor I grabbed the side of the fuselage, which is, well, pretty darn sharp. It sliced into my hand down to the tendons.... Pretty disturbing to see... Ouch. That brought a premature end to my work session today (I took today and tomorrow off).

Sunday, July 21, 2019

3 hrs. yesterday on misc.

This banjo fitting had to be swapped in for the plug that was there. Won't torque it until I'm sure of the orientation.

Finally got around to organizing my clamps..

When I upholstered the luggage compartment I had forgotten that the channel that covers the parachute compartment has to come off to install the parachute. Fortunately it came off easily.

Since I've got some missing fittings and lots of questions, both of which I'm hoping to resolve at Oshkosh, I'm trying to work on things other than the engine. I'll paint and install this strip which gets screwed into the fiberglass of the canopy.

These seem to match what's in the manual, but I only have 3 sets, when it appears I need 4. Hmm...

But, they also fit here and the new Tsi/4 manual for the firewall forward seems to show these types of fittings as opposed to the kind shown in the older 4 manual. One of my many questions....

Kerry was over helping out and did the circuit work for this stuff. Almost done.

This banjo fitting had to be swapped in for the plug that was there. Won't torque it until I'm sure of the orientation.

Finally got around to organizing my clamps..

When I upholstered the luggage compartment I had forgotten that the channel that covers the parachute compartment has to come off to install the parachute. Fortunately it came off easily.

Since I've got some missing fittings and lots of questions, both of which I'm hoping to resolve at Oshkosh, I'm trying to work on things other than the engine. I'll paint and install this strip which gets screwed into the fiberglass of the canopy.

These seem to match what's in the manual, but I only have 3 sets, when it appears I need 4. Hmm...

But, they also fit here and the new Tsi/4 manual for the firewall forward seems to show these types of fittings as opposed to the kind shown in the older 4 manual. One of my many questions....

Kerry was over helping out and did the circuit work for this stuff. Almost done.

Friday, July 19, 2019

1.5 hrs. on the oil system.

Since I'm waiting for the fuel pump manifold I started to look at the oil system.

This fits, but it doesn't look like what's in the manual or the factory photos... I can't seem to find any parts that look like the factory photo parts for these fittings. Hmm...

It says 5/16" ID hose, but I don't think that can be right. 1 - That's smaller than what the Rotax manual says is acceptable and 2 - Size 22 OET clamps would be way too big for 5/16" hose. I think it's the larger hose I have, but I'll confirm.

The manual spec. Bigger than 5/16".

Oil thermostat assembly.

The holes need to be enlarged (at least they did for me). 6mm drill bit for these two holes and 6.5mm bit for the 4 side holes.

Tightened it all up...

...assembled....

...But, a bit premature on those rubber mounts.... They need to be a bit loose to screw into the engine holes.

I think these are the necessary fittings. The manual doesn't say what goes where on this. But, I'm hoping there's a 4 at Oshkosh and I can take lots of photos with more detail than the factory photos.

My wife made this from our backyard raspberries and some homemade whip cream... Delicious.

Since I'm waiting for the fuel pump manifold I started to look at the oil system.

This fits, but it doesn't look like what's in the manual or the factory photos... I can't seem to find any parts that look like the factory photo parts for these fittings. Hmm...

It says 5/16" ID hose, but I don't think that can be right. 1 - That's smaller than what the Rotax manual says is acceptable and 2 - Size 22 OET clamps would be way too big for 5/16" hose. I think it's the larger hose I have, but I'll confirm.

The manual spec. Bigger than 5/16".

Oil thermostat assembly.

The holes need to be enlarged (at least they did for me). 6mm drill bit for these two holes and 6.5mm bit for the 4 side holes.

Tightened it all up...

...assembled....

...But, a bit premature on those rubber mounts.... They need to be a bit loose to screw into the engine holes.

I think these are the necessary fittings. The manual doesn't say what goes where on this. But, I'm hoping there's a 4 at Oshkosh and I can take lots of photos with more detail than the factory photos.

My wife made this from our backyard raspberries and some homemade whip cream... Delicious.

Looking at the FT-60 fuel flow transducer documentation it's clear that the transducer must go between the pumps and the fuel regulator on the Rotax, so it can't go inside the cabin before the pumps. Just means I have to re-do the connections to the regulator, but I still think that's easier than cutting into the metal tube to a carb and doing brazing.

Thursday, July 18, 2019

1 hr. contemplating my navel...

Some of my original LED lights have been dying lately so I've been using a portable halogen work light. Problem was, that light was ridiculously hot, so I bought another LED light to replace it. Didn't realize how huge it would be! Good lighting makes a huge difference in the ease of working on anything!

The picture doesn't do it justice, but it's crazy bright. Unless I'm shooting a feature film, I'll probably just point it up to reflect off the ceiling... Blinding...

Starting to think about the sensors that have to go on the engine and noticed this little nugget on the SteinAir circuit diagrams - it has two fuel flow transducers (out and return)... I'd have to buy another FT-60 (OSH discount!), but doing it this way would be way easier than silver soldering fittings on a metal fuel line. I could put them just inside the firewall, maybe on some bracket I can fashion. You wouldn't want them dangling on some of the existing fuel lines on the engine side since they're supposed to be mounted horizontally in a preferred orientation. I like this better, but I'll think about it some more.

Do I have the Oil Pressure Sensor, Oil Temp Sensor, Coolant Temp Sensor, Air Box Temp Sensor? Are they already on the engine? Pawing through my parts I don't see them. Some research ahead...

I did find the Fuel Pressure and Manifold Pressure Sensors. They look exactly the same, but if you look closely you can see they have different part numbers on the sides.

Some of my original LED lights have been dying lately so I've been using a portable halogen work light. Problem was, that light was ridiculously hot, so I bought another LED light to replace it. Didn't realize how huge it would be! Good lighting makes a huge difference in the ease of working on anything!

The picture doesn't do it justice, but it's crazy bright. Unless I'm shooting a feature film, I'll probably just point it up to reflect off the ceiling... Blinding...

Starting to think about the sensors that have to go on the engine and noticed this little nugget on the SteinAir circuit diagrams - it has two fuel flow transducers (out and return)... I'd have to buy another FT-60 (OSH discount!), but doing it this way would be way easier than silver soldering fittings on a metal fuel line. I could put them just inside the firewall, maybe on some bracket I can fashion. You wouldn't want them dangling on some of the existing fuel lines on the engine side since they're supposed to be mounted horizontally in a preferred orientation. I like this better, but I'll think about it some more.

Do I have the Oil Pressure Sensor, Oil Temp Sensor, Coolant Temp Sensor, Air Box Temp Sensor? Are they already on the engine? Pawing through my parts I don't see them. Some research ahead...

I did find the Fuel Pressure and Manifold Pressure Sensors. They look exactly the same, but if you look closely you can see they have different part numbers on the sides.

Subscribe to:

Comments (Atom)