Flew yesterday and no more nose wheel shaking on climbout, so the imbalance is resolved!

Categories

ailerons

(16)

avionics

(141)

electrical

(180)

elevator

(23)

Empennage

(55)

firewall forward

(222)

flaps

(12)

fuel cells

(68)

fuselage

(596)

horizontal stabilizer

(14)

instructions

(3)

interior

(104)

paint

(36)

Painting Planes

(3)

panel

(67)

propeller

(3)

rudder

(16)

seats

(5)

ServiceBulletin

(1)

shop

(33)

Sling Central

(23)

tools

(41)

vertical stabilizer

(20)

video

(37)

welcome

(22)

wheels

(44)

wings

(147)

Tuesday, May 17, 2022

Did three practice approaches with my CFII.

Sunday, May 15, 2022

Did an oil change this weekend and since I hadn't cleaned the oil tank yet, I did that. I've decided to do my oil changes at 30-hour intervals. My detailed checklist for oil changes is at the bottom of this post.

Oil drained....

- If replacing spark plugs (every other oil change), gap 8 of them to 0.6mm (0.023") to 0.7mm (0.027")

- Warm-up engine to operating temperature

- Remove upper cowl

- Remove keys!

- Detach air intake from the NACA duct

- Remove lower cowl

- Burp engine

- Get sample container

- Put on gloves (there's lead in that oil!)

- Remove drain plug bolt (using 17mm and 19mm wrenches (the 19 is used to hold the tank nut so you're not twisting the tank))

- Drain oil - Take a sample from mid-stream of oil draining for oil analysis (I use Blackstone Labs)

- If cleaning the tank (every third oil change) ( Video Part 2 below for how to clean the tank of lead sludge):

- Loosen top cover and two worm clamps

- Remove tank and clean

- Reinstall tank and cover

- Safety wire cover latch

- Reinstall drain valve with new crush washer to 25Nm (18.5 ft-lb) (Groove facing down)

- Safety wire drain plug bolt

- Prepare a new filter with an oiled gasket surface

- Remove oil filter, protecting components underneath with paper towels/towel since oil will leak

- Put on new filter until fully touching

- 3/4 more turn

- Magnetic plug:

- Remove safety wire

- Use paper towels to protect parts from dripping oil

- Use 16 mm socket to loosen (may need a long-armed wrench)

- No whiskers longer than 3mm in length

- It should feel like a fine metallic paste

- Clean plug and re-install to 25 Nm (18.5 ft-lb) (Really should be 100 in-lb (8.33 Ft-lb) because threads are oiled)

- Safety wire

- Remove dipstick (so you’re not covering it in oil)

- Add 2.5 L

- Turn prop 20+ times

- If replacing spark plugs (every other oil change)

- Remove spark plugs and inspect (see below)

- Inspect cylinders & valves with a boroscope

- Put thermal paste sparingly on spark plugs threads (3 threads closest to electrodes should be clean) and install to 20 Nm (177 in-lb)

- Put lower cowl on

- Reattach air intake to the NACA duct

- Run engine to operating temp and make sure oil pressure rises within 30 seconds

- Remove keys

- Check for leaks

- Burp engine

- Check level before adding the final .5 L (Should be in the upper half of the min/max range (max if you're going on a long flight))

- Put upper cowl on

- Note Engine Time & Total Time in Engine Logbook

- Cut open the oil filter to inspect.

Thursday, May 12, 2022

Well, the weather has really sucked these past several months. I'm flying whenever it's been flyable, though mostly with my CFII to keep my instrument training moving along.

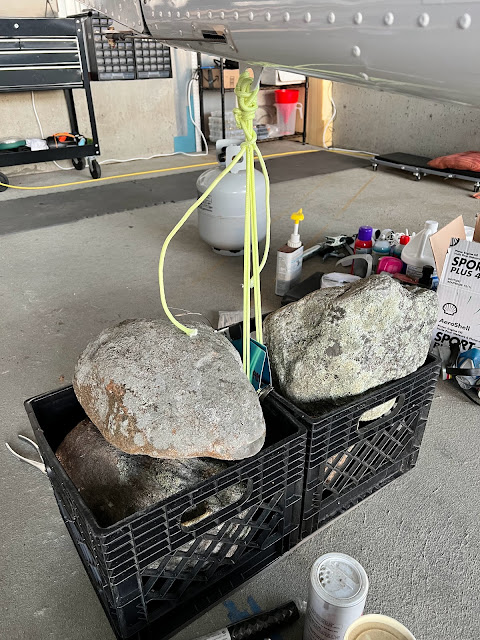

One thing I've noticed for a while is nosewheel vibration on climbout. Just lasts for 20 seconds or so and I've just assumed it was some kind of aerodynamic thing at that speed and pitch. I posted about it on Facebook and several people said it was more likely that the nose wheel was out of balance. So, I looked into that a few days ago.

Pants off...

Subscribe to:

Comments (Atom)