The pattern of holes on my part doesn't match the manual so I figured out the closest matching holes for the stop bolts.

If you over-tighten those bolts it just beings these pieces together, which you don't want to do, so don't over-tighten.

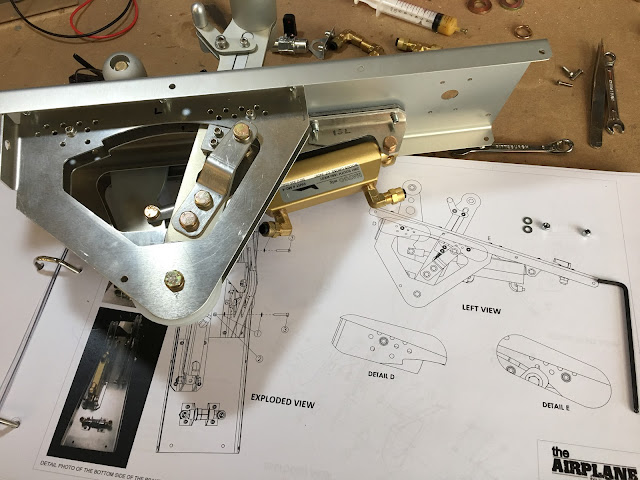

Starting on the seat adjustment assembly. I figured out that the plastic pieces connecting to the channels would be easier to rivet before putting in the channels.

Moving right along...

Ended up having to drill out some of the rivets you see here...

The pin with the spring, washer and split pin inserted.

Coming together.

Uh oh, 10 of these rivets will need to come out...

Standard 8mm 3.2 sized rivets aren't long enough to engage the 2 layers of plastic here, so I drilled it out to 4.0 and used those instead (10mm long, which is just barely long enough).

Rivets drilled out...

Hmmm... How to get the plastic parts and associated hardware behind the cable while having basically no access underneath...

Unrelated to the above: I knew these parts went somewhere and I figured out where (with help from other blogs). These go underneath these floor panels.

No comments:

Post a Comment