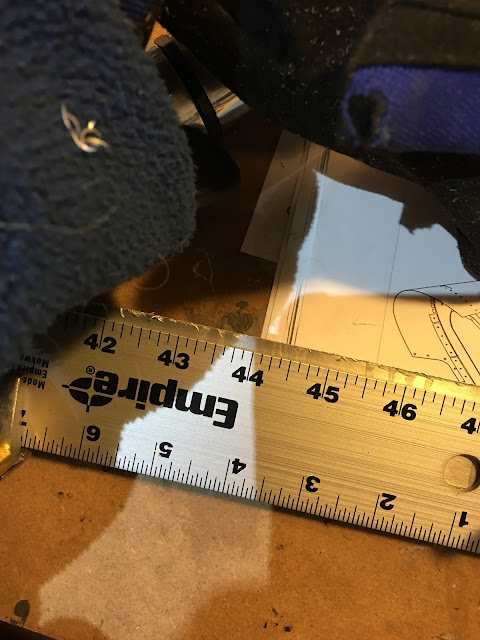

Clamped down a straightedge on my test material and ran the nibbler along it. Turns out the distance from the straightedge to the cut is exactly 5mm. Note the crescent-shaped shards on my sleeve.

After removing the plastic film and deburring the edge it looks pretty darn perfect.

My test of cutting along a curve on this trashed landing light plate (from a previous failed experiment with a jig saw...). Test is to remove the material to the line.

And it works pretty well. Not perfect, but good enough for this task.

And the final result (I also ran a Dremel with a Scotchbrite wheel along the edge to smooth it)- not perfect, but good enough. There's probably a better way to have done this, but I don't have that tool...

Now I need the 25mm buttonhead screws that are missing from my kit...

Holding a 4' straightedge along the leading edge shows a slight gap in the area of the landing lights. Problem?

NEXT SESSION:

- Need to wait until Wednesday to remove the tank and test for seal.

No comments:

Post a Comment