1.5 hrs. on the nose wheel.

Widening those holes with the manual reamer was tediously slow... Hey, no one said I couldn't put the manual reamer in a drill. :-) Worked like a champ. Still accurate, but MUCH faster. Just make sure not to go too far.

It's a beautiful thing. ;-) I'll trim off that long top later.

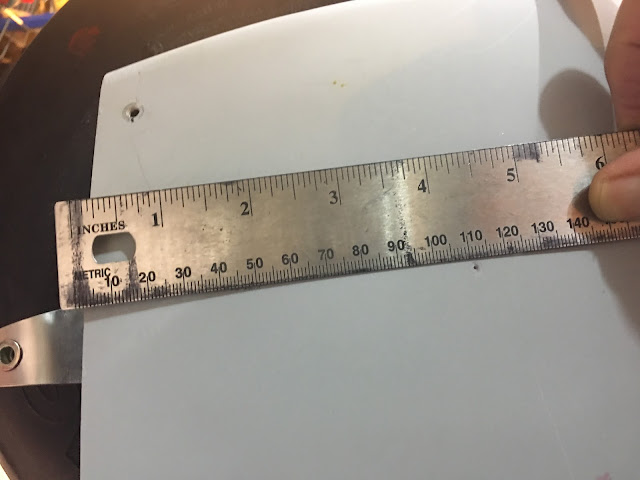

The four holes for attaching the spat to the gear are dimpled. This one looked fine, but the next one didn't, so I measured this one against the other one. This is about 112mm from the edge.

To the center of the misshapen hole is about 114mm, so I don't think this side is right. Before I drill anything, let's see how it fits and scope things out.

Here's the fit.

I marked off 112mm, but I don't want to drill those front holes yet.

Maybe hard to see here, but there's a gap between the rivnut and the front spat. You can actually see photos of Slings where the spat is pulled in. We don't want that, so I'm going to do what Bob Zaleski recommended and use Sugru, a moldable glue to span that gap. I already have that material on hand.

I drilled the two back holes that had more precise dimples and put in the M5 buttonhead screws. With those located I can be more confident in locating the front holes properly. To be done either tomorrow or Saturday.

I think you will find that putting the spats on for winter is a bad idea. They get clogged with snow and you can't preflight the brake pads.

ReplyDeleteWell, easy enough to remove them for the winter if I see that happening.

Delete