3 hrs. finishing the cabin heat exhaust shroud and starting to look at the fuel system.

Tightened up and the extender that I riveted on works perfectly to fit the gap.

I don't know why but my two ends don't overlap enough to use the existing holes. I can't imagine it was something I did because it's simply a matter of circumference. It's tight around, but it doesn't overlap much. My solution is further down this post...

Applied my fire shield sealant around the inlet to the cabin heat box.

Hose cut to length, pushed and twisted on and clamped.

Full view. I'll tie it down as shown in the manual.

A bit hard to see in this pic, but instead of spending an hour trying to figure out how to use the existing holes, I drilled new holes and filled the old holes with fire shield sealant. Also put on longer bolts with some washers and all-metal locknuts for the clamps at both ends of the shroud. Note that you should not rivet on the inlet side at this time. We'll get back to that after the bottom cowling is on.

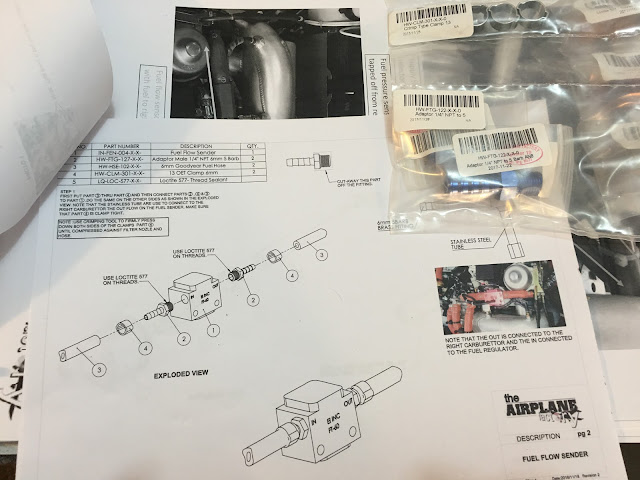

Starting to look at the fuel system and finding I don't have some of the parts... I'll chalk this up to being a very early customer (1st in the USA for the 4...), but I've had lots of mismatches between the inventory lists, my actual inventory and what's in the manual. The fitting in the package is for larger hose than what's shown in the manual (and it's a different part number). No, I don't have the part number shown in the manual anywhere else in my inventory...

BTW, if you're a more recent builder I'm assuming you'd have far less issues with your inventory than I've had.

The manual indicates that I have to cut off a section of the line to the carb and do some "silver soldering"... No idea how to do that and not totally comfortable trusting my non-existent skills to the fuel system... Hmm...

More missing or incorrect parts... Lots of fittings to 8mm hose, but no 6mm barb fittings. And the part numbers don't match...

I don't know what "leaving equal outer ends" means.

The fittings that was packed in the with the fuel pressure sender doesn't fit the 8mm hose it's supposed to fit in. Too small.

silver soldering is not much different than regular soldering, just a little hotter iron required. The solder is different than tin or lead/tin and so is the flux.

ReplyDeleteI'll have to look into it. Not sure how comfortable I am with this task...

Delete