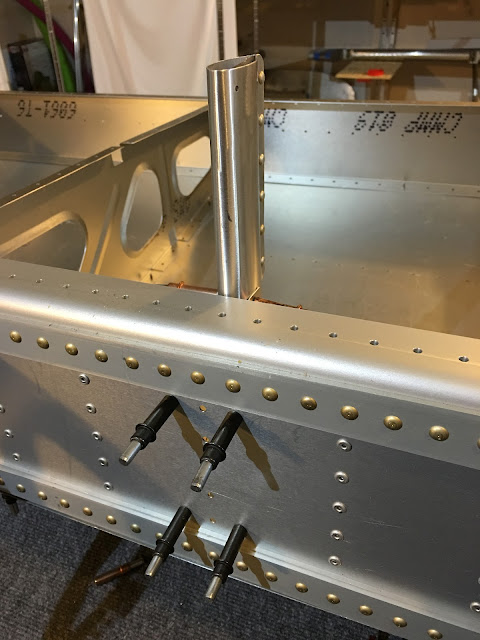

Pitot assembly cleco'ed in.

Turns out I don't need to cut the hole for the pitot, it's already in the skin. Ahh...

Bottom skins fit nice.

Time-lapse video of working the leading edge skin around the ribs.

And the leading edge skin fits too.

NEXT SESSIONS:

- Forgot this: Just like the right wing there are holes along the main spar that don't line up with the bottom skin, so those need to be drilled.

- Flip to top

- Remove top skins and leading edge skin and rivet ribs and pitot assembly.

- Flip to bottom

- Rivet bottom skins (STRINGER!).

- Flip to top

- Wiring in.

- Landing lights in and tested. Test wing tip lights.

- Air lines in.

- Fitting and final sealing of left wing fuel tank. Tank off and test for seal.

- Inspection of both wings by EAA Tech Counselor.

- Fuel tank on. Just bolted at this point.

- Top skins riveted on (STRINGERS!).

- Leading edge riveted on (STRINGER!).

- Rivet fuel tank on.

- Wing tip assembly and light installation.

- Fill rivets with Bondo.

- Finish right wing (14, 15, 16, 17, 18, 19, 20).

- Finally finish one of the composite tips of the elevator.

- Fill rivets of elevator with Bondo.

- START ON FUSELAGE!

No comments:

Post a Comment